The Art of Indigo - an Aizome Adventure Part I

- Olivia Brantner

- Aug 1, 2020

- 3 min read

While in Japan, I took it upon myself to immerse myself in as much of Japan's creative culture as possible. One simply cannot delve into the creative history there without coming face to face with 藍染め (Aizome), the Japanese art of indigo dyeing. Known as JAPAN BLUE, the shades of blue created by Aizome are just stunning - the deepest shades are rich and full and the lightest are soft and gentle.

I had not one, but two opportunities to get hands-on with Aizome during my time in Japan. The first was at the heart of the indigo dyeing industry in Japan, the city of Tokushima on the island of Shikoku. On an unassuming street with a somewhat hard to find entrance is Ai-No-Yakata, one of only a few remaining workshops that hand-makes natural Japanese indigo dye from start to finish.

At Ai-No-Yakata, it is possible to have a go at dyeing using some traditional pattern-making methods. A small group of wizened and wise ladies run the workshop and you can see their devotion to their craft in their hands - their fingers and nails are all stained blue from many years working with the dye.

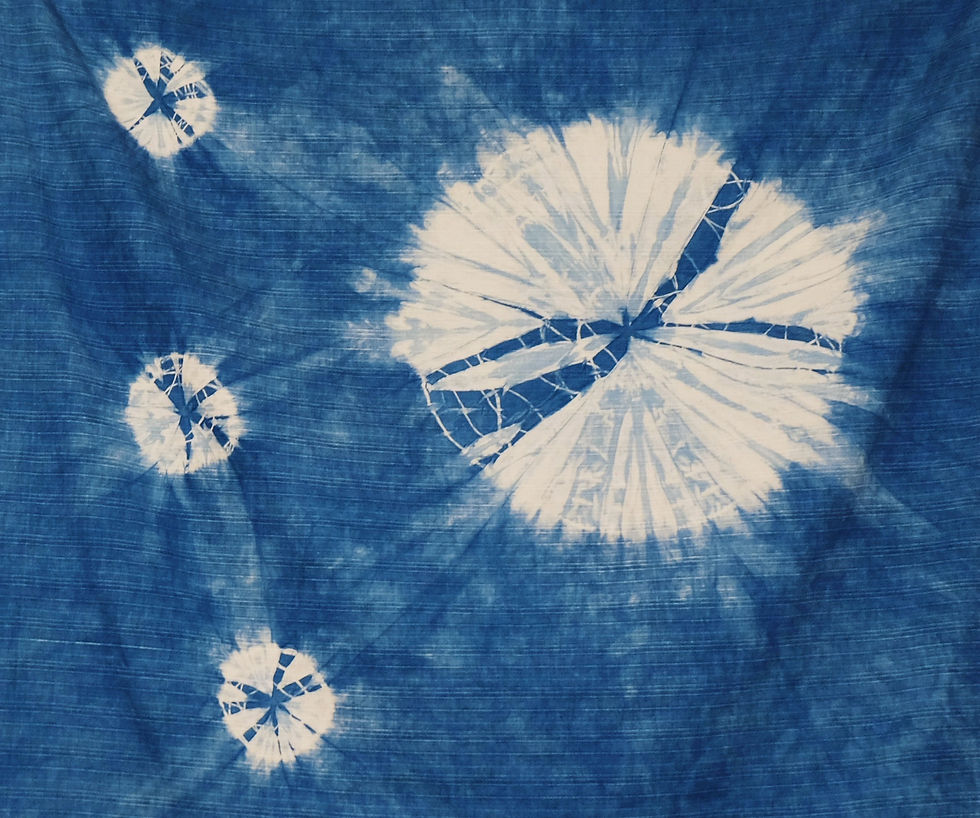

I was with my father, who was visiting from the States, and we each dyed our own item. I dyed a large 風呂敷 (furoshiki), a traditional square cloth used for wrapping and carrying just about anything, and my father brought with him a white linen shirt. I wanted to try my hand at some 蜘蛛絞り (kumo shibori), a style that uses a dowel and thread (or in this case rubber bands) wrapping technique. The word 蜘蛛 (kumo) means spider in Japanese so it follows that the resulting design bears a resemblance to a spider's web. My father simply wanted to dye his shirt a solid, deep indigo without any patterns.

I do not have any photos of my creation in its pre-dyed glory or while it was soaking in the giant vats of dye since my hands were full and then covered in indigo. But, I have a few from around the workshop after.

The entrance, where a dyed 暖簾 (noren) hangs.

A furoshiki hangs in between the prep room and the workshop.

The prep room - you can see some examples of techniques on the walls.

You must wear an apron! Indigo is an extremely strong dye and once on it might fade with time and washing but will never come out completely.

The workshop has two rooms. In the front room were some traditional round vats full of dye.

Aizome is made through a fermentation process so the surface of a vat of dye will usually have a frothy film on it. This is a result of the fermentation and vigorous mixing that must be routinely done in order to keep the dye from settling. The liquid dye looks almost like it is a deep inky purple in the vats - it is hard to visualize the shades of blue it will yield when staring into their depths.

The back room, where my father and I dyed our items, held a series of rectangular vats. The wooden covers have become a shade of blue from the years of being handled with hands drenched in ink. Even the concrete floors have taken on a blue tint. That is how powerful this dye is!

Here is my father's shirt having just been taken out of the vat. Notice that the shirt has an almost deep green color - this is because the Aizome process is not yet finished once the item is removed. Aizome requires oxygen in order to oxidize. With rinsing and exposure to the air, this deep emerald will change to a deep indigo.

After dyeing, a good long rinse is needed. Here is my furoshiki getting it's bath.

The finished products out for a dry under the sun. You can see how my father's shirt has changed hue and where the fabric is thicker along the seams, the blue is lighter. My furoshiki came out alright - next time there will be some more planning since I am not super happy with the layout but I might hem it make it smaller and thus make the designs fit more nicely. But I love the individual elements.

A little closer look at my kumo shibori designs.

On a last note, what strikes me most about Aizumi, besides its unquestionable beauty, is the mark it leaves on those who produce and use it. As I mentioned above, those who produce it often have hands and fingernails permanently stained blue - a constant reminder of the dedication to such a labor-intensive craft. I only touched the dye briefly when I rinsed out my dyed cloth; only a fraction of the strength of the inky dye fermenting in the giant vats. Yet, even so, my fingertips gained a light dusting of blue. This dye is powerful, enough so to last centuries.

Stay tuned for part II - an Aizome adventure in Tokyo!

Comments